Products By goods

Panels

Use Cases

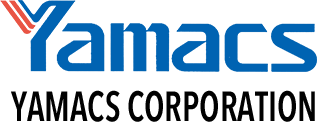

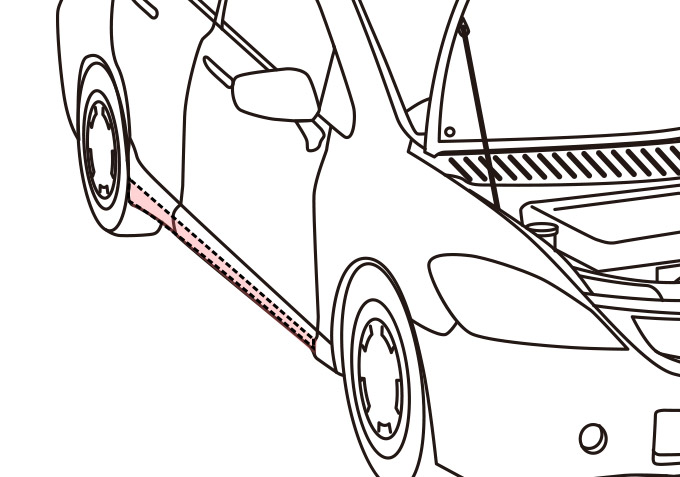

Car Manufacturer

| Used for: | Car |

|---|---|

| Product used: | Panels |

| Print method: | Silkscreen printing |

Problem

The name of the model on the scuff plate is different depending on whether the car is sold for domestic or overseas use. Need to avoid over/under stocking from having different names for domestic and overseas car sales.

Yamacs’ Proposal

Yamacs recommended replacing only the logo portion of the model name with metallic print (Cubee).

Solution

The metallic print goes well with the stainless steel of the scuff plate to give a fully integrated feel.

Result

The car manufacturer was able to prevent overstocking and relieve pressure on purchasing by ordering only the panels needed for each model after ensuring the same material needed for total number of cars in Japan and overseas.

Customer Feedback

We were able to get a low purchase price while maintaining the quality of appearance. (Designer)

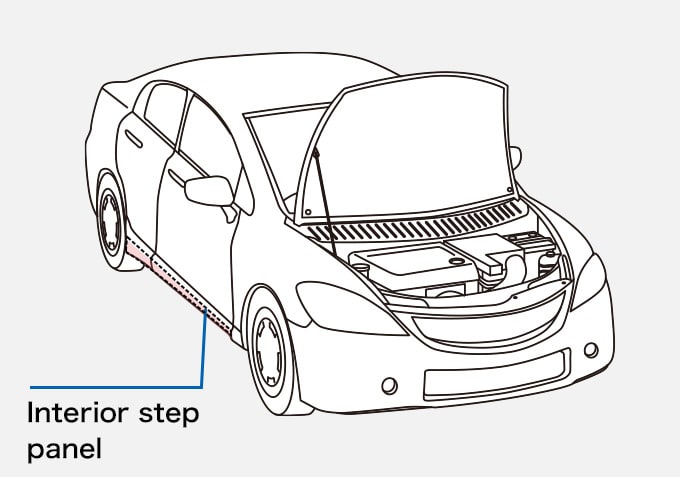

Cosmetics Manufacturer

| Used for: | Compact case |

|---|---|

| Product used: | Panel |

| Print method: | Silkscreen printing |

Problem

Where an intricate design is required or when a mold or plating is needed for one-off cosmetic products, etc., it is not effective to do in small quantities. There is a limit to what can be down with the design when printing directly on containers or when hot stamping.

Yamacs’ Proposal

Yamacs recommended a very designable UV film print.

Solution

We first proposed inserting a UV printing film into the compact case whose lid is shaped into two parts, and then evaluated its appearance.

Result

As the compact case could be used for other product purposes the UV printing meant the case could be used again, something which wasn’t possible with the conventional direct print / hot stamping designs. This helped avoid overstocking of the cases.

The design was also highly regarded meaning it could be used for limited-edition / small run products.

Customer Feedback

I was very happy with the quality for our limited-edition cosmetics and small run products. (Designer)

Cosmetics Manufacturer

| Used for: | Compact Case |

|---|---|

| Product used: | Panels |

| Print method: | Inkjet printing |

Problem

The manufacturer wants to use a decorative sheet for a cosmetics case as one its planned products. If using silkscreen printing the many different types and colors stretches the budget too much, and it is also difficult to reproduce the intricate pattern of the design.

Yamacs’ Proposal

Yamacs recommended inkjet printing for the decorative design.

Solution

Various designs were trialled to see how well the designs and patterns could be reproduced.

Result

There were no problems reproducing the patterns in the trials. With inkjet printing a printing plate is no longer needed so it was possible to reproduce the intricate designs, something which was difficult with other print methods.

Customer Feedback

Using inkjet printing we were able to recreate the traditional Japanese pattern with its many different colors. (Designer)

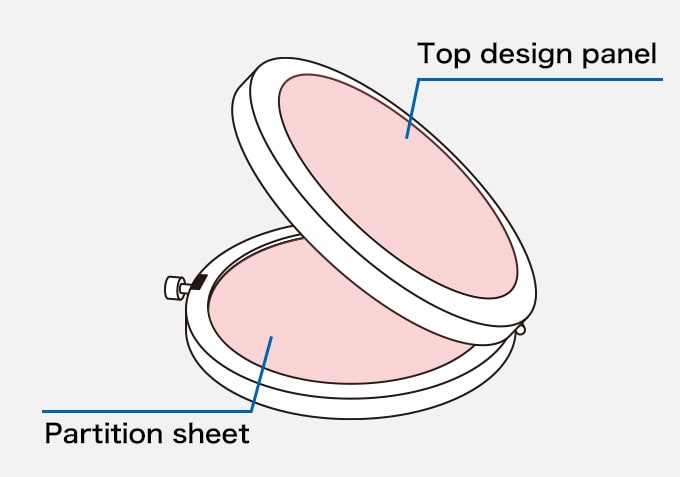

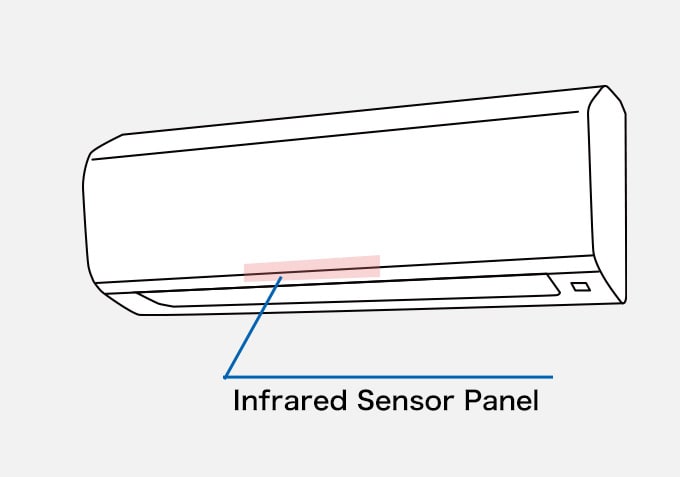

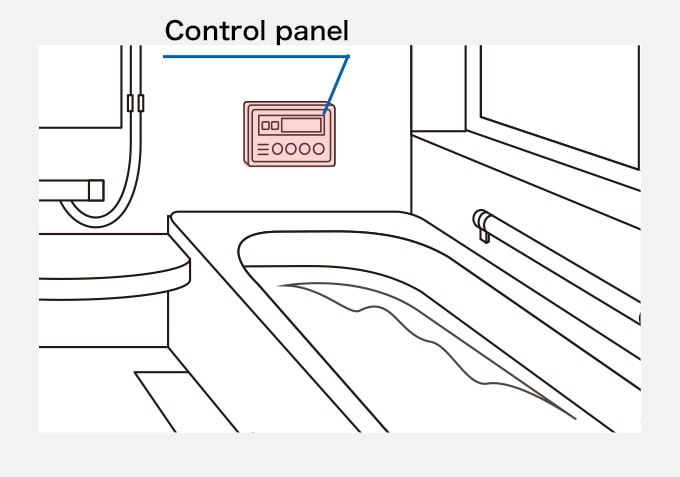

Home Appliance Manufacturer

| Used for: | Air-conditioner |

|---|---|

| Product used: | Design / function panel |

| Print method: | Silkscreen printing |

Problem

The plastic infrared sensor part of the air conditioner was costly, came only in black, was fairly thick and needed to be rounded in shape.

Yamacs’ Proposal

Yamacs recommended infrared transparent printing.

Solution

We created a prototype with the transmittance and color the client wanted, and measured and verified the transmittance in-house.

Result

We were able to reduce costs compared with plastic parts. Printing with infrared we were able to get the exact same color of the air-con unit (white or gray) which the client wanted and we were able to print and display lettering.

And because infrared transmittance could be measured in-house, we were able to make that guarantee in line with the client’s requirements.

Customer Feedback

It was hugely significant for us to get the finish we wanted in terms of both appearance and performance, and to solve the problems we had in the past of processing and letter display. (Technician)

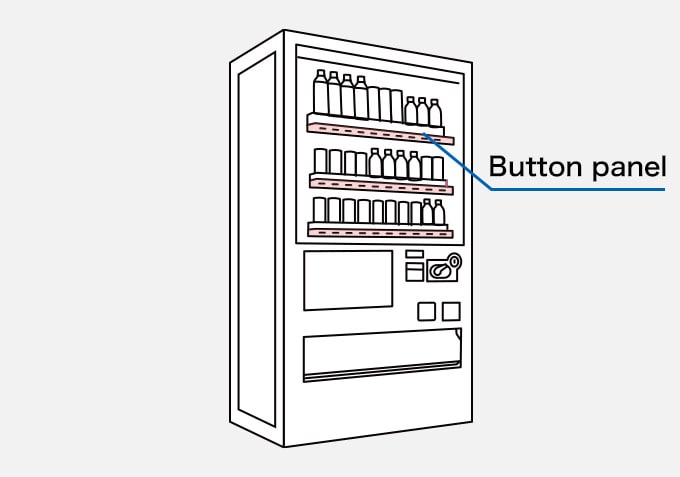

Vending Machine Manufacturer

| Used for: | Vending machine |

|---|---|

| Product used: | Button panel |

| Print method: | Silkscreen printing |

Problem

To improve visibility, the button display unit is made up of a molded cover for the LED lights, a molded part to diffuse the light, and a display sheet. Because of the number of parts and the time it takes in putting them together, it is costly.

Yamacs’ Proposal

Yamacs recommended printing a display sheet using light diffusing ink.

Solution

Using the diffusion effect of the molded part (of the vending machine which diffuses light) as a sample, ink composition was continually adjusted with repeated tests carried out on the vending machine. The result was that we were able to get the same level of diffusion with just the display sheet.

Result

Less parts as requested by client, reducing assembling time leading to lower costs.

Customer Feedback

Not only have costs been minimized, but because there are now less parts we have also been able to slim down the machines, something which we’ve been focused on doing recently. (Technician)

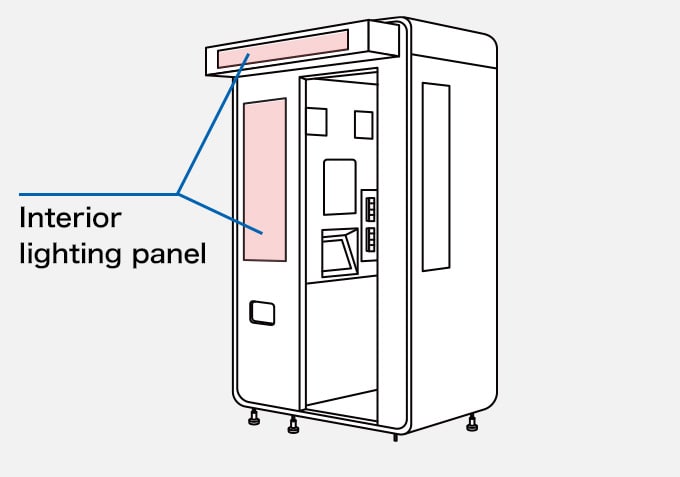

Manufacturer of Industrial Equipment

| Used for: | Photo booth |

|---|---|

| Product used: | Interior lighting panel |

| Print method: | Inkjet printing / silkscreen printing |

Problem

The interior lighting panel, the photo booth’s sign, was done in offset printing but the colors faded quickly meaning the product did not look good.

Yamacs’ Proposal

Yamacs recommended the use of both inkjet and silkscreen printing.

Solution

As well as checking the design in trials, we carried out weather resistance tests in-house, further validating the results.

Result

The design was finished to the same degree as that done with offset printing owing to the inkjet output, and by combining this with silkscreen printing the weather resistance was significantly improved. At the same time, it was possible to prevent the Newton’s rings effect by enclosing the product in a film when installing the booth.

Customer Feedback

The finish was good, the weather resistance was improved, and the cost was kept down. (Materials manager)

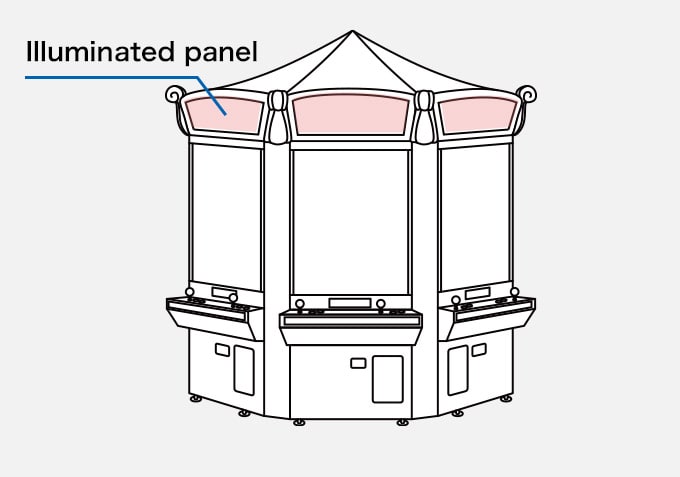

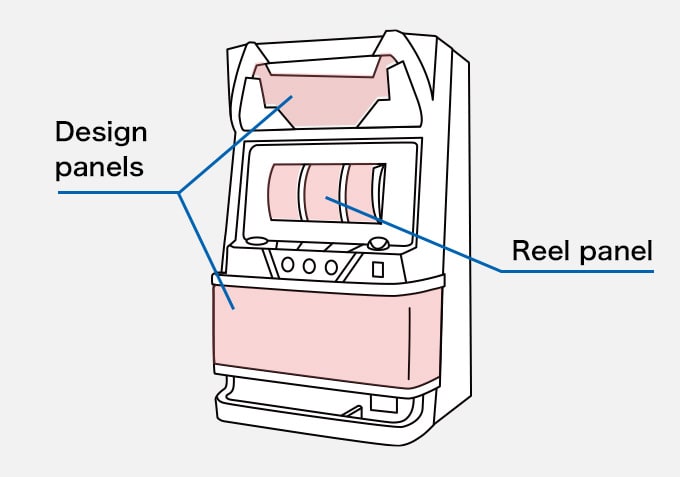

Game Machine Manufacturer

| Used for: | Slot machine |

|---|---|

| Product used: | Design panels |

| Print method: | Silkscreen printing |

Problem

The LED lighting from the back of the design panel allows character images to show through. However, because the color of the image is given from the light behind, the color seen is not known unless the panel is fixed in place. Also, if any light escapes the panel at the bottom loses its effectiveness.

Yamacs’ Proposal

Yamacs recommended the use of a color toning technology which recognizes the light source and adjusts if any light escapes.

Solution

An extra thick ink is used for the colors which cannot normally be reproduced when using regular ink. The colors are then checked using the actual machine or a similar light source. The colored parts where light does not pass through have the color/shade balance adjusted.

Result

No problems with both saturation and brightness in terms of the transparent part of the design. And no problems with the base color or light leakage.

Customer Feedback

I’m very happy with the finish which doesn’t diminish the game’s concept or the character’s image. (Designer)

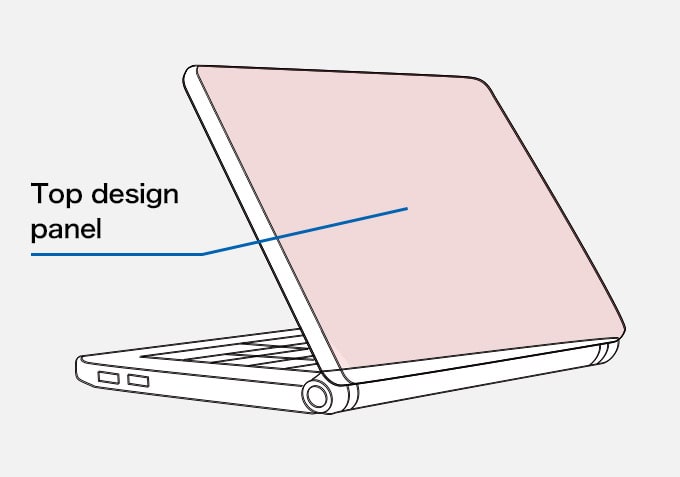

Manufacturer of Office Equipment

| Used for: | Laptop computer |

|---|---|

| Product used: | Design panels |

| Print method: | Silkscreen printing |

Problem

The manufacturer wants to adorn the top of the laptop with a high-end design.

But the laptop itself (the part where design goes) is magnesium.

Yamacs’ Proposal

Yamacs recommended metallic 3D printing (Cubee) to give a high-end feel.

Solution

Design affixed using the three dimension overlay method (TOM). Developed a hot melt adhesive for integral molding.

Result

Normally, the design is printed directly or painted in a single color, but the use of panels improves the degree of freedom in design. The design also met the requirements for a high-end feel. And by sticking with a molding machine the design has been given a solid finish.

Customer Feedback

Despite sales only taking place online without any advertising, I was surprised the laptop sold out immediately. (Designer)